Desoutter: Overview

History of an innovative brand

Desoutter Industrial Tools has a rich history of innovation and growth, with several subsidiaries specializing in electric power tools, intelligent tools, bolted joint applications, advanced drilling solutions and Real-time location system.

The origins of a great dynasty

In 1914, the Desoutter brothers, all passionate aviators, faced a life-changing event when Marcel lost a leg in a plane crash. His brother Charles, determined to restore Marcel’s mobility, designed a groundbreaking artificial leg made of duralumin, marking the world’s first metal leg. This innovation allowed Marcel to fly again with ease. The Desoutter Company was born from this success, as orders poured in from around the globe. Some years later, in 1946, a French Secretary of State asked the company to manufacture “A utility one, not as elaborate or expensive”. The reply given by Robert, one of the Desoutter brothers, was irrevocable: “We make the finest artificial leg there is, if we could make a better one we would (…) But we will not make a cheap one.” This care for excellence has never since been compromised.

The Horse's head, from advertisement to company emblem

Charles Cunliffe, who led Desoutter’s Advertising department after World War II, conceived the symbol. During a period of robust growth driven by innovative tools, they launched an eye-catching campaign featuring small figures in worker’s overalls with horse heads. This horsepower concept effectively conveyed the Desoutter toolset’s strength and became a central theme in brand advertisements for two decades. In 1973, the horse’s head merged with the Desoutter logo, which replicated Louis Albert Desoutter’s signature, a company founder. Since then, it has symbolized the brand across industrial nations, recently adopting a more contemporary design to celebrate the brand’s centenary.

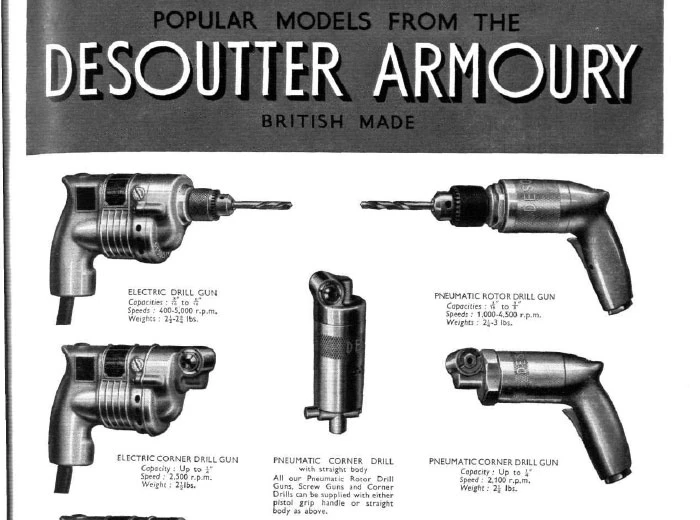

From artificial limbs to power tool manufacturing

From the outset, Desoutter needed to develop specific pneumatic tools to ensure that the aluminum components of the artificial limbs were drilled quickly and efficiently. Constantly perfected to adjust to the numerous developments in its production, the company acquired such expertise in this field that in the 1950s they decided to make it their sole business. Since then, the same care for excellence behind the success of its artificial limbs was applied to developing ever more efficient and powerful portable precision tools. Its ability to adapt to the specific needs of its clients and the reliability of its products meant that it quickly captured the foreign market to become a key international player.

Desoutter, a century of innovation at the service of efficiency in industry

Founded under Taylorism and Fordism, Desoutter felt from the start the necessity to include the innovations it produced in a more global context taking into account both the individual and its environment. Unlike its competitors, the company was particularly quick to understand the notion of ergonomics in the development process of its products with an eye to improving their use. Lastly, true to its values and slogan, “More than Productivity”, Desoutter has been committed to eco-friendly development by adapting its production tooling to environmental standards

A World Leader

True to its philosophy “Worldwide Solutions with Local Expertise” and in accordance with the brand’s promise of “More than productivity”, Desoutter has endeavoured to strengthen its position in the market by timely mergers with other companies of renowned expertise. In this way the French companies Georges Renault and Seti-Tec, the American Tech-motive, the Swedish Scan Rotor, the UK Pivotware and the German nexonar have enhanced Desoutter’s offer and enabled the brand to benefit from local sales networks and services which ensure its development throughout the world.

At present, with over twenty business units and one thousand collaborators in over fifty countries, the company aims to be the number 1 strategic assembly solution provider and cover most requirements for assembly and manufacturing processes in the automotive, aeronautics, general industry and light industry sectors alike.

For more articles about Desoutter products Click Here

Click the link here to view and download the entire Desoutter Catalog

Contact us with any questions or for more information